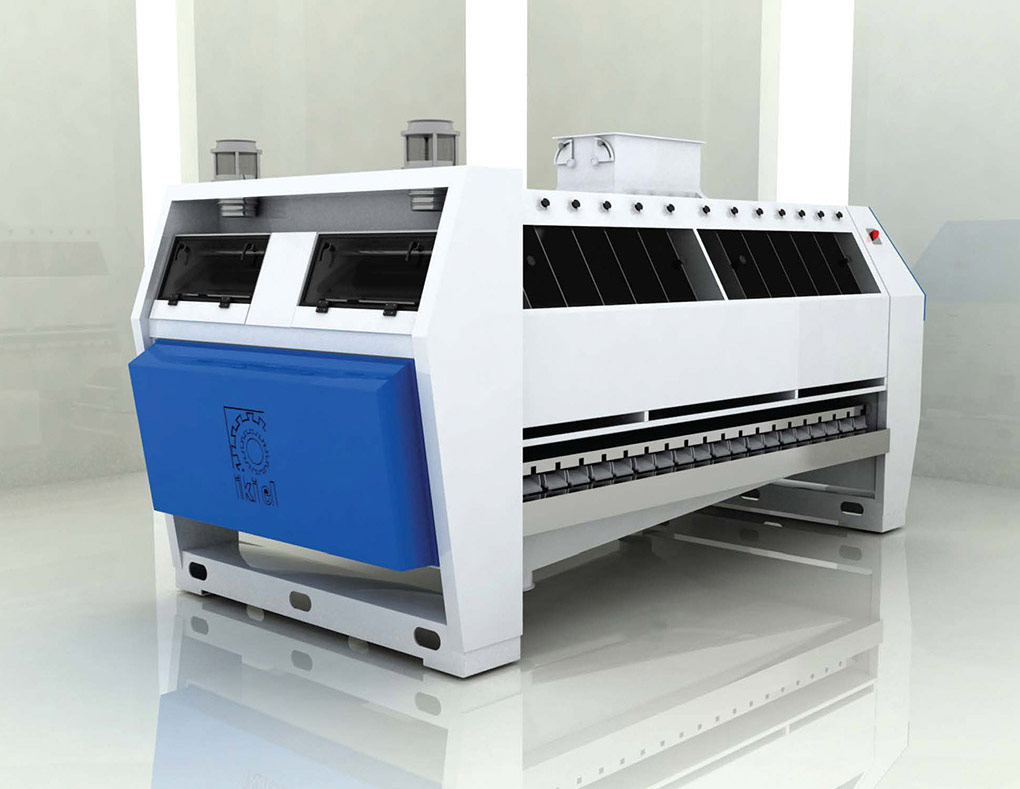

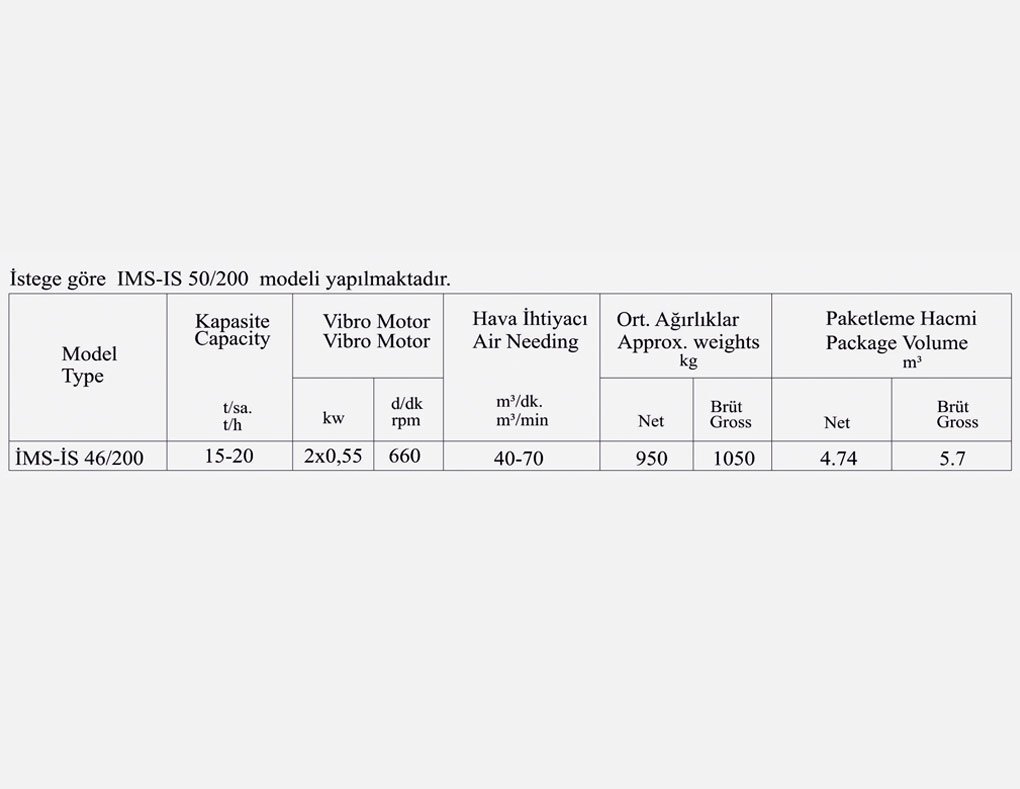

SEMOLINA PURIFIER İMS-İS 46-200

- The system is used for cleaning and classification of semolina, in flour and semolina mills.

- The flow rate of product can be adjusted and by means of a regulating plate, the product can be spread uniformly on the surface of the screen.

- The screening process is carried out by 2 or 3 layers oftelero.

- By means of aerodynamic air duct and air regulating valves, the optimum vacuum effect is obtained on the surface of screen. Bran and similar products are separated from the semolina and transferred to discharge outlet. The product (semolina) which is separates from bran, is classified in according to size of grain by using screens.

Features

- High capacity by using larger screens.

- Effective cleaning by using brushes.

- Adjustable screening speed.

- Trouble-free working conditions and minimum periodic maintenance by means of vibromotors.

- Silent operation.

- Easy cleaning process and hygenic working conditions.

- Light metalic screen frames with adjustable tightening device and easy replaceable screens.

- Hygenic working conditions are obtained by sellecting right and optimum ventilation. Therefore it is possible to keep always clean internal surfaces of the aspiration ducts.

- Practical, quick and easy handing, cleaning possibilities.

Scroll to top