SQUARE PLANSIFTER İMS-KAE

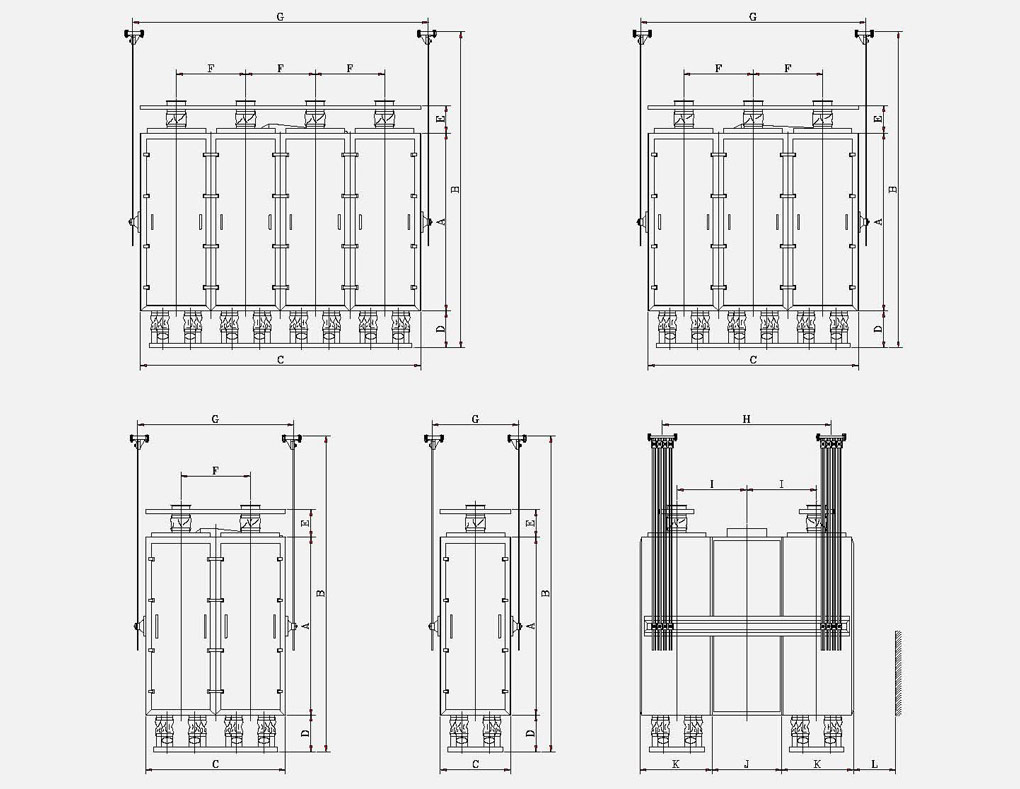

Square plansifter is a machine in the flour mill in which plays vel}’ important role in processing to produce of flour. The machine is used for sifting and classifying grinded grain by roller mill machine. Processing of sifting is arranged according to milling diagramme. The plansifter is consist of following main parts;

- Compartment as two pieces (sifter section)

- Chasis (drive section)

- Swinging parts at both side

Compartments are fastened to chassis by bolts and in this situation the plansifter hang to ceiling through oscillation parts by hanging rods.

Theplansifter are designed for sifting of various different grams, wheat, rye, maize and also drum mills.

Specification

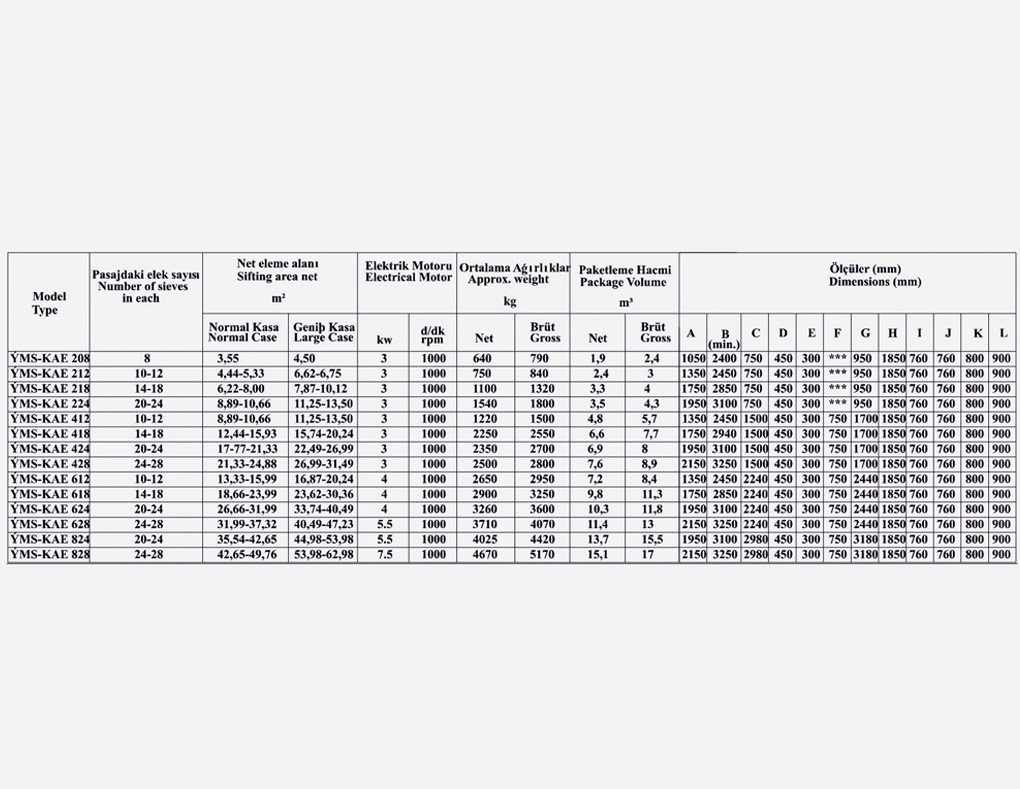

Net sifting area of 19to 55 m2 depending on the type of sieves,

Steel construction,

For gaining maximum capacity intensive motion,

Up to 18-26 sieve per compartment,

Wood sieves with coated formica,

Noisless and efficiently sieve cleaning,

Sieve trays of tih plated sheet steel, (option; formica)

Easy changing of the frames regarding to requirement,

Easy cleaning,

Minimum maintenance, optimum sanitation,

For transportation easiness, partial loading.

How operates

The plansifters are applied in

- Flour mills

- Semolina mills

- Maize, rye, oat mills

- For every sort of grain

To be sifted product is fed by one or more inlet pipes to the sieve area.

Different types of frame allows to separate seven canals.

For on fraction is directed by the channel to the sieve frames for outleting. After sifting the product is sent to outlet spout in the bottom plate. Also there are inspection holes on the outlet pipes, for inspecting and controlling the product.