Flat-Based Silo

Production of Flat based silos can be made from 50 tons to 15.000 tons in diameters ranging between 4.51 m and 31.60 m and these silos can also be manufactured as conical based according to the needs.

High quality galvanized sheets used in silo production is resistant to 450 MPA tension and corrosion and the galvanized coating standard of sheets are 450 gr/m2 and 350 gr/m2. Galvenized coating ratio may vary as per order.

Our silos have the capacity for maximum storing in return of minimum area and cost and the raw material loss has been reduced to zero.

Quick solutions are created with the opportunity of onsite assembly and demounting by screqing together.

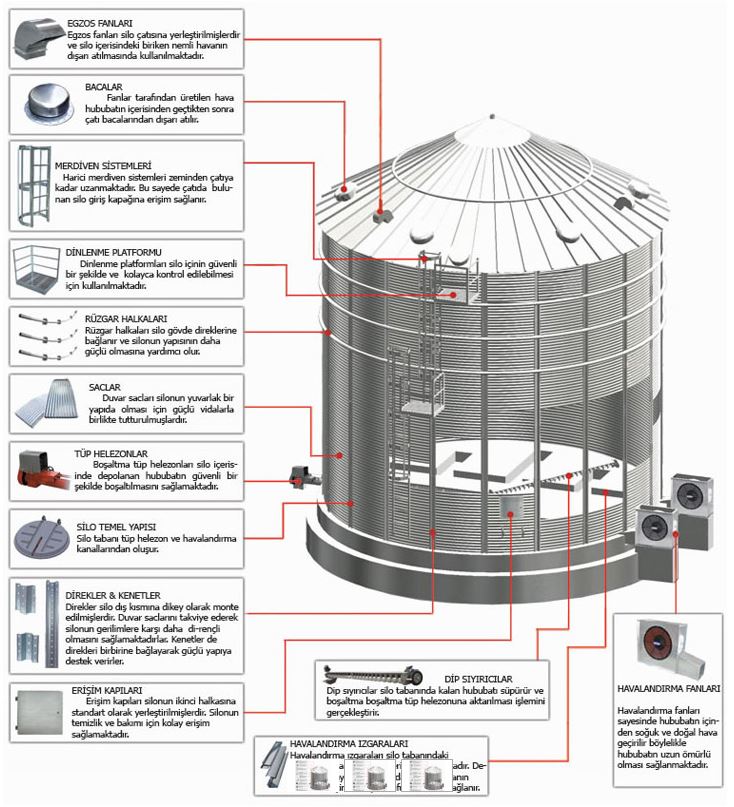

Turco steel silos have a security antrance door and monitoring cover on its roof. Silo entrance door is duplex. Exterior is made of solid galvanized sheet and the interior flat comprises of two doors placed one after another. If the grain amount inside the silo exceeds the height of the entrance door on the nonitoring cober on the roof.

On their exterior surfaces, all turco silos are equipped with exterior ladders with security cage and platform for resting. Roofs are built in lattice from with the use of special section profiles in order to increase the durability and service life of upper roofs of grain silos with a wide diameter and thanks to this structure, the durability of the silo roof reaches maximum level.

The heat control system used in silos creates easy solutions by allowing you to determine hot areas and pest activity. The intergration of heat control system into PLC enables controlling the heat of grain inside the silo on PLC display.